Level Up TIG Welding in Just 7 Days: Your Route to Success

TIG welding fundamentals.

Have you ever watched a metal artist skillfully melt and fuse pieces together with the grace of an aerospace welder? That's the beauty of TIG welding process. You may think that you will never reach that stage.

Well, I'm here to tell you that it is possible! Picture this: by next week, your hands confidently guiding an electric arc as easily as writing your name.

We're talking about unlocking a new world where precision meets power; where artistry dances with science. Stick around and let’s embark on this transformative journey together!

Table of Contents:

Understanding TIG Welding Basics

The Principles Behind GTAW

Essential Equipment for TIG Welding

Selecting Your Shielding Gas

Tungsten Electrodes Types

TIG Welder Components & Filler Materials Selection

Choosing Right Tungsten Electrode

Setting Up Your Machine

Mastering TIG Welding Techniques

The Art of Arc Control

Filler Metal Deposition Techniques

Pipe Welding with TIG

Welding Dissimilar Metals

Pulse Settings for Heat Control

Comparing TIG Welding with Other Methods

Transition from MIG to TIG

The Upsides and Downsides of Each Method

FAQs in Relation to Master the Art of Tig Welding in Just 7 Days

How long does it take to master TIG welding?

Can I teach myself to TIG weld?

Is TIG The Hardest to learn?

Why is TIG so hard to learn?

Understanding TIG Welding Basics

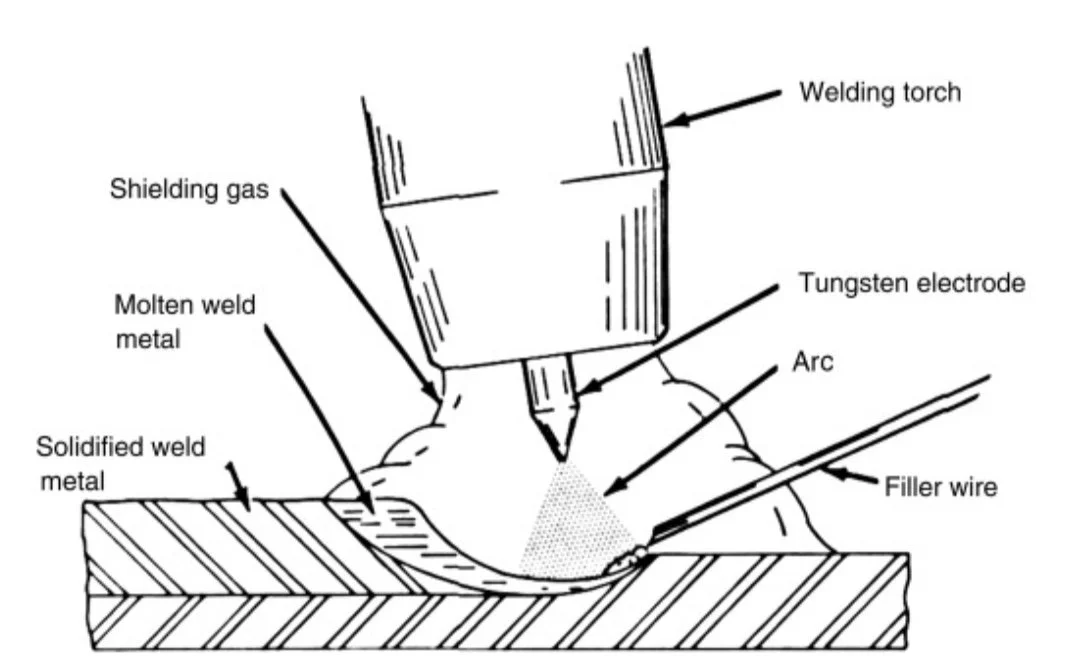

For those prepared to embark on a welding journey, it is essential to comprehend the fundamentals of TIG welding. This unique welding process uses a non-consumable tungsten electrode to create an electric arc, generating enough heat for metal fusion.

The Principles Behind GTAW

Image 1: GTAW principles. Notice the argon gas creates a “blanket” of inert shielding gas around the molten weld metal.

Gas Tungsten Arc Welding (GTAW), or more commonly known as the TIG welding process, stands out from other techniques because it offers incredible control over your welds. How does this work? It's all about that tiny bit of tungsten and inert gas shielding.

The key component in this setup is the non-consumable tungsten electrode which forms an electric arc with your workpiece. By controlling this arc’s intensity, you can manipulate how much heat goes into your weld—kinda like turning up the burner on a stove when you want things cooking faster.

Inert gas shielding plays a significant role too by protecting your molten pool from atmospheric contaminants that could mess up its purity and strength using an external gas shield. So, while argon gets busy playing bodyguard to your weld pool, let's move onto some hard stats.

You should know: compared to MIG welding; mastering TIG welding steel needs more practice and coordination—it's slower but not without its rewards.

Lincoln Electric, renowned for their high-quality machines highlight that using AC power source allows alternating between positive and negative currents ensuring effective cleaning action alongside penetration during aluminum TIG welds.

A DC power source gives us deep penetration ideal for steels where cleaning isn’t needed.

We also have mixed options – both AC & DC currents – to cover a wide range of metals.

Alright, if you're eager to push your welding abilities to the next level, getting a handle on TIG is transformative. Yes, it's akin to juggling while pedaling a unicycle—tough at first—but with time and patience, you'll be crafting cleaner welds of superior quality that are truly worth their weight in gold.

“Interestingly, musicians and gamers have an advantage in learning TIG welding due to their developed hand-eye coordination.”

Essential Equipment for TIG Welding

When it comes to mastering the art of TIG welding, understanding your equipment is key. Each component plays a significant role in achieving that perfect TIG welded job.

Image 2: TIG welder equipment and setup. Notice how current travels from the weld machine to the torch and back.

Selecting Your Shielding Gas

The first thing you'll need to get started with is choosing the right shielding gas. It's like picking out the best defender for your team; its job is to protect the molten metal from contamination. And who does this job better than Argon? Argon, being the most commonly used shielding gas in TIG and welding processes, provides excellent arc stability and prevents oxidation.

It is generally considered that argon is the most suitable shielding gas for your application. Argon is widely used in many industries and TIG welding applications. Welding engineers may choose helium when they need to increase the welding speed, as helium generates more heat than argon and can be more efficient in some cases.

If we were comparing gases on a leaderboard, argon would be sitting comfortably at number one spot. But remember: just as different sports require different defenders, certain materials may benefit more from other gases or mixes depending on their properties.

Tungsten Electrodes Types

Moving onto our star player - The tungsten electrode. This little guy forms an electric arc with your workpiece when power passes through it. Choosing which type can feel like auditioning actors for a movie role – they all look similar but have unique characteristics that make them shine.

TIG Welder Components & Filler Materials Selection

No set-up would be complete without considering both your machine’s components and filler material selection (kinda like how no burger should go without fries.). When selecting fillers think about compatibility with base metals while considering tensile strength and corrosion resistance too.

YesWelder, has great resources that provide detailed information about setting up TIG machines optimally.

To help you out, I've decided to put together a handy list of essential TIG welding equipment:

Tungsten Electrodes: The star player in the process.

Shielding Gas: Your defender against contamination.

Arc Power Source: Sets up your playing field for success.

To wrap it up, it all boils down to having the right crew (gear) in place.

Image 3: AI interpretation of a TIG welder.

“Argon protects the molten weld pool from the atmosphere while the tungsten directs the arc.”

Preparing for TIG Welding

The process of preparing for a successful TIG welding project involves more than just donning your safety gear and switching on the welding machine. It starts with meticulous cleaning of the weld area of your workpiece.

Cleaning is essential because any contamination, be it rust, oil, or dust particles can interfere with the quality of your welds. To ensure that you get high-quality welds every time, make sure to use a stainless steel brush or chemical cleaner specifically designed for this task.

Next up in our preparation journey is joint preparation. Depending on what type of joint you're working with - whether it's butt joints, lap joints or corner joints - each requires different considerations when prepping them up before we let sparks fly.

Image 4: The effect of tungsten grind angle on weld penetration. Notice how the depth of penetration varies with the difference in tungsten grind angle. The sharper the tungsten electrode, the shallower and wider the penetration; the blunter electrode diameter, the deeper and narrower.

Choosing Right Tungsten Electrode

Selecting an appropriate tungsten electrode isn't as simple as picking one at random from the bunch; there are several factors to consider such as size and material compatibility. You'll want to match these characteristics according to the thickness and type of metal you plan on welding.

Your choice could mean the difference between clean smooth beads versus ones filled with pinholes and undercutting. Remember: knowledge gives power – wield yours wisely.

Cleaning Your Metal

The most important step in welding is cleaning and preparing the weld joint. The recommended method is:

Use a Scotch-Brite pad to buff out the surface layer

File away any burrs

Acetone wipe the joint

The point is to obtain a shiny, clean surface to weld. If your metal has any burrs, surface scale, or rust, you must stop and clean your metal before proceeding. Do not skip this step.

Setting Up Your Machine

Last but certainly not least in our prep-work is setting up your trusty TIG machine itself. This step might seem daunting at first glance given all those knobs and dials staring back at you... But fear not. With some patience (and perhaps help from AMI's helpful guides) even beginners can become masters at dialling in their machines like pros.

No two welding jobs are alike, so don't expect a single setting to work for all projects - you'll need to fine-tune your amperage, gas flow rate and electrode stick-out through trial and error. It'll take some experimentation to find the perfect balance between amperage, gas flow rate and electrode stick-out. But with time, you’ll get a feel for what works best.

Let's get this straight - prepping isn't just an opening act, it is the headliner. It's the main event itself.

“Mastering TIG welding is all about nailing the prep work: making sure your piece is clean to dodge any contamination.”

Mastering TIG Welding Techniques

If you're ready to step up your welding game, understanding the art of arc control is vital. This skill helps maintain a consistent and stable welding arc during TIG welding, resulting in better welds and high quality welds.

Image 5: Aluminum welder using GTAW. Notice the aluminum filler rod “balled-up”. That means the welder lingered around the arc for too long and the heat caused the rod to ball up.

The Art of Arc Control

Arc control may seem daunting at first but trust me; it's more about rhythm than complexity. Think of it as dancing - once you get the beat right, everything else falls into place. Starting and controlling the arc involves finding that perfect balance between electrode distance and amperage setting.

But let's not stop there. When working with different materials or thicknesses, your technique will need some tweaks. For instance, welding thin materials versus thick materials demands an entirely different approach when using TIG welding techniques.

Fear not. The beauty lies within practice – keep going until each movement feels natural to you.

Filler Metal Deposition Techniques

Image 6: Rush Kane using his signature feeding technique.

Beyond just striking an arc, knowing how to use filler metal effectively can make all the difference in your final product’s strength and appearance. To master this craft isn't rocket science; it's more like cooking pasta: every ingredient matters.

The best way to feed filler wire is by holding the rod between two contact points. This way, the end of the filler rod will not shake, like if you were to feed using the traditional filler hand technique.

Your rod angle should be around 20 degrees from vertical while feeding into the leading edge weld puddle for the most effective deposition. The American Welding Society offers great tips on this aspect too.

Pipe Welding with TIG

What's next? Pipe welding, my friend. When it comes to pipe welding with TIG, consistency is king. Picture yourself as a marathon runner pacing himself – you need that same rhythm and focus for this task.

This practice demands patience and precision but don't sweat it. Remember, Rome wasn’t built in a day; neither will your skill be.

“Stepping up your TIG welding game involves mastering arc control, adapting techniques for different materials and thicknesses, using filler metal effectively, and practicing patience in aerospace welding”

Advanced Tips for TIG Welding

TIG welding is an art form that can be refined with practice, persistence, and the right tips. One area where seasoned welders excel is in welding exotic metals using TIG techniques. But don't fret. You too can master this skill.

The first step to successful exotic metal welding involves understanding your material's unique characteristics. For instance, titanium has a high melting point but requires careful heat control due to its reactive nature. On the other hand, aluminum conducts heat rapidly and thus demands quick yet precise movements.

Welding Dissimilar Metals

An advanced technique worth learning in your journey as a welder is joining dissimilar metals - like welding stainless steel with copper or nickel alloys with carbon steel. It may seem daunting at first glance; however, it's achievable by choosing the correct filler materials and following suitable procedures from reliable sources such as American Welding Society Certified Welder Program.

Pulse Settings for Heat Control

Moving on to pulse settings - these are integral when you need enhanced control over heat input without compromising speed or quality of workmanship.

Pulsed TIG allows current variation between peak (high) levels used for penetration and background (low) levels allowing cooling time without extinguishing the arc entirely. This results in lesser distortion while maintaining a cleaner appearance because less filler material ends up being deposited.

Peak Current: Determines penetration depth and width of bead.

Background Current: Regulates how much base metal stays molten between pulses.

Pulse Frequency: Dictates how fast we transition between peak/background currents per second.

Note: While there's no 'one-size-fits-all' pulse setting, a good starting point for many is 1 PPS (pulse per second) with peak time at 60% and background current around 30%. Experimentation is key here.

Wrapping up, TIG welding can seem intimidating for beginners. Once you become proficient in TIG welding and other welding processes, you can get a high-paying aerospace welding job.

AI’s interpretation of GTAW.

“Mastering TIG welding, especially with exotic metals, starts by understanding their unique properties. Techniques like joining dissimilar metals and controlling heat input via pulse settings can elevate your skills.”

Comparing TIG Welding with Other Methods

TIG welding, sometimes referred to as Gas Tungsten Arc Welding (GTAW), is a popular selection for many welders. But how does it stack up against other methods of shielded metal arc welding like Stick or MIG? Let's dig deeper.

Transition from MIG to TIG

Moving from Metal Inert Gas (MIG) arc welding processes to Tungsten Inert Gas (TIG) can feel like jumping out of a comfortable car and hopping onto a high-speed train. While both are arc welding techniques, they offer distinct advantages and disadvantages that need consideration.

Making the switch requires you to master new skills such as foot pedal control for heat adjustment - something not needed in MIG. However, once you've mastered this skillset, your precision levels skyrocket compared to stick welding. So while the transition may be challenging at first glance, think about it as an upgrade rather than just another task on your list.

The Upsides and Downsides of Each Method

Talking about advantages and disadvantages of TIG welding, let’s begin by acknowledging its superiority when it comes to clean finishes free from spatter - something every perfectionist would appreciate.

In comparison though, SMAW or 'stick' offers more flexibility with different types of metals including those rusted or dirty surfaces where cleanliness isn’t exactly next-to-godliness.

MethodClean Finish?Flexibility With Metals?TIGYesNoSMAW ('Stick')NoYes

So, what's the bottom line? Picking the right one really comes down to the art of TIG welding.

Ever wondered how TIG welding compares to other methods? From precision levels that soar above stick welding, to clean finishes perfectionists love, it's a high-speed train of skills. But remember - no method is one-size-fits-all.

On the last day of your training, you'll have an opportunity to demonstrate all that you've learned and perfected in the TIG process of welding. You'll focus on mastering the art of TIG welding by refining your techniques, improving your precision, and achieving consistent, high-quality welds.

By adhering to this well-organized weeklong training program, you'll be on the path towards becoming an accomplished TIG welder. Continuing to practice and refine your skills after the 7-day training plan will help you become an expert TIG welder.

For additional resources and opportunities to further develop your TIG welding skills, consider checking out organizations like The Crucible and Laney College.

FAQs in Relation to Master the Art of Tig Welding in Just 7 Days

How long does it take to master TIG welding?

TIG welding mastery varies by individual, but with a solid 7-day training plan, you can learn the fundamentals and start practicing effectively.

Can I teach myself to TIG weld?

Absolutely. Self-guided resources like online tutorials or books can be invaluable. However, hands-on practice is key in mastering this skill.

Is TIG The Hardest to learn?

TIG tends to be harder than other methods because of its precision requirement and coordination needs between both hands. But don't worry - patience brings perfection.

Why is TIG so hard to learn?

The difficulty comes from needing simultaneous control over heat (via foot pedal), filler material feeding and welding torch manipulation. It's complex but not impossible.

Conclusion

You've learned the TIG welding basics, explored its key components and principles. Now you understand how to use an AC/DC power source, a non-consumable tungsten electrode, and inert gas to form an arc and create a weld.

You're equipped with knowledge on selecting your shielding gas. You know argon is commonly the gas shield in TIG welding but other gases have their places too.

And then there's preparation for TIG welding – cleaning workpieces or setting up TIG welding machines - all part of your new skillset now!

We've also touched on mastering techniques like arc control that will help improve the quality of your welds significantly.

By diving into advanced tips, we’ve ensured you’re ready for complex projects! And remember when we compared TIG Welding with other methods? It was enlightening to see where each method shines best.

Last but not least: our 7-day training plan showed you it’s possible to Master the Art of TIG Welding in Just 7 Days!

The world of precision meeting power; artistry dancing with science is within reach now...and I'm excited about what this means for you!